HEAT EXCHANGE DONE RIGHT

In the swiftly evolving industrial sector, each year there is a growing need for temperature control equipment. Such equipment must be able to efficiently heat or cool raw materials and chemical products while minimizing energy consumption. PLATECOIL heat exchangers easily fulfill all these requirements, and are even designed for specific applications.

Features

- Available in dipping, clamp-on, vessel, and warmer variations

- Reduced energy consumption via highly efficient heating/cooling

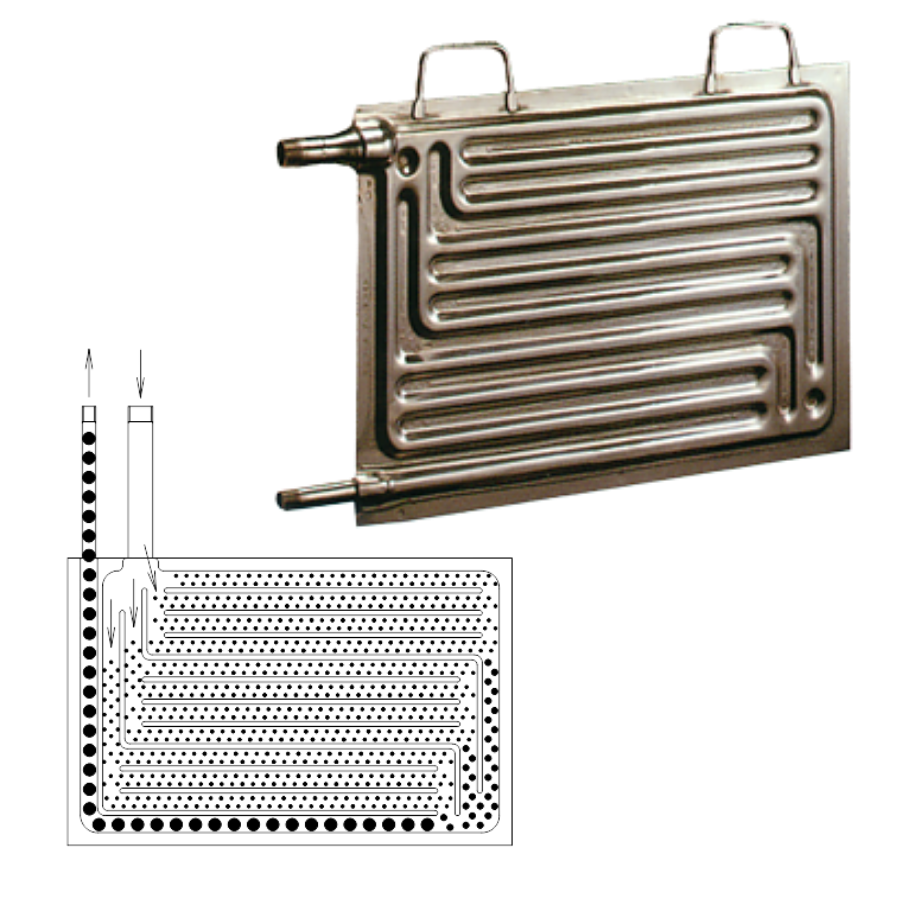

- High thermal transfer due to unique press-formed construction

- Custom shapes for a variety of industries including chemical processing, food production, automotive applications, as well as electronics, and power sectors

PLATECOIL VARIATIONS

DIPPING TYPE

- Comes in a variety of sizes and dimensions

- Lightweight, high strength solution

- Applications include pretreatment heating and drainage cooling

CLAMP-ON TYPE

- Quick retrofitting solution for existing equipment

- Easy installation & maintenance – no welding required

- Applications include brewing tank cooling and raw material tank heating

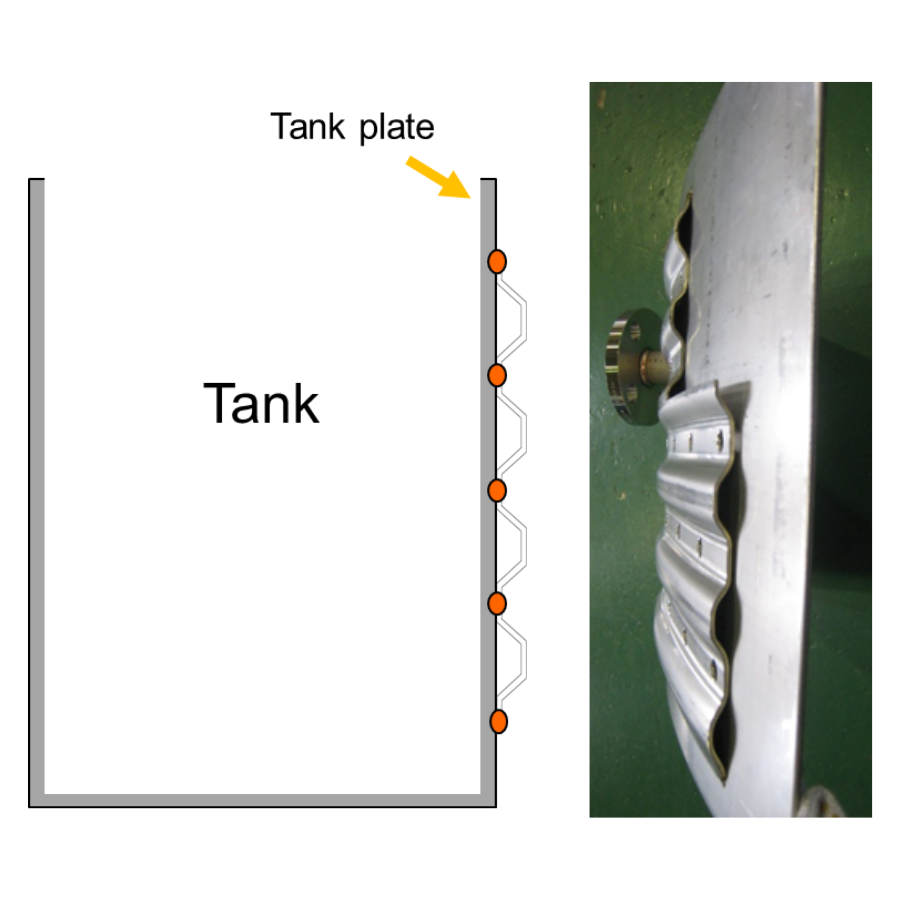

VESSEL TYPE

- Reduces vessel wall thickness requirement

- Can be installed on existing thin vessel walls

- Applications include reactor vessel heating/cooling and kneading or mixing machine cooling

DRUM WARMER TYPE

- Quick and easy to move and mount

- Can be attached to standard 200L drum

- Also available as compressed gas cylinder warmer or can warmer variants